Side Stream Filtration (SSF)

The cooling tower water used for industrial/process applications or comfort cooling requires for a filtration system for suspended solids and a chemical or nonchemical based scale preventing/removal system. A cooling tower water treatment system is necessary in ensuring an efficient process and long equipment service life for your connecting components (heat exchangers, evaporative condensers, cooling tower basin, piping system and more) and downstream equipment.

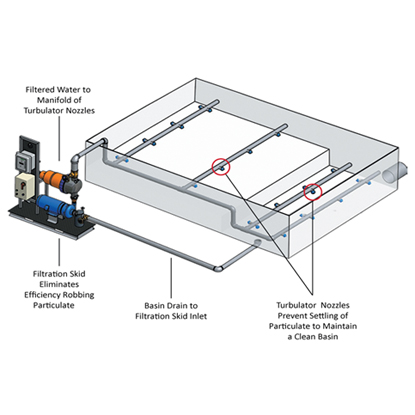

Side stream filtration is used to filter a portion of the systems circulating water, removing debris and particles that are adversely affecting the cooling loop and its components (heat exchangers, chillers and more).

Over time, filtering 10% - 20% of the cooling loop flow results in the filtration of the total volume of water every 12 – 72 hours. The filtration rate will highly depend on the application and filtration technology at hand.

Side stream filtration technology generally falls into the following categories: screen filters, centrifugal filters, bag & cartridge filters, sand/media filters and high efficiency media filters.

The screen-filtering element acts as a barrier, removing all particulate (both organic and inorganic) down to 10 microns. Automatic self-cleaning screen filters are becoming the filter technology of choice for cooling tower filtration applications requiring removal of particles 10 microns and larger. During the self-cleaning process, this technology yields the least flushing discharge.

Screen filters also provide uninterrupted filtration during the cleaning process, thereby requiring only a single filter for continuous 24/7 filtration.

Premium Quality Products

with Large Sales and Service Network

Most trusted by many

recognised Brands in India

Honored with Recognitions

and Certifications

Brochures & Manuals

You can download the informational brochures or the user manuals for our products