Basin Sweeping Systems (BSS)

Water in cooling towers attracts and absorbs large volumes of airborne contaminants on a continuous basis which can build up and settle within the system. Predominantly, the contaminants in the system are sand, silt, scale and rust. These contribute to the excessive creation of deposits (scale, corrosion, bio-fouling and biological activity), negatively impacting heat transfer efficiency. Solids accumulation in Cooling Towers and Condensers cause increased bacteria growth a potential health risks.

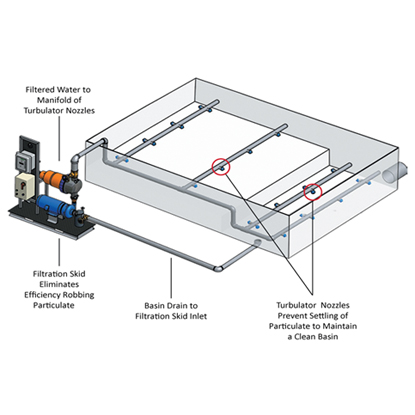

Basin Sweeping is used to filter a portion of the systems circulating water, removing debris and particles and returning the filtered water to the water basin of the cooling tower through turbulator eductor nozzles placed in the basin. The filtered water returned to the basin is used to “sweep” the dirt towards the filtration system inlet thus keeping the solids from ever entering the cooling system. While the application of side stream filtration depends on the application, most applications will benefit from a basin sweeping system from both an efficiency, and an economic standpoint. Basin sweeping systems can work as standalone or paired with side stream filtration.

Turbulator Basin Agitation Systems when used in conjunction with filter skids that include a pump, turbulator agitation nozzles will remove suspended solids at the source, keep solids suspended at the source to prevent settling, provide cleaner water to chiller. Significantly reduces cooling tower blow-down cycles and saves water. Minimizes maintenance cost and maximizes cooling system and process equipment life.

Brochures & Manuals

You can download the informational brochures or the user manuals for our products

-

Premium Quality Products

with Large Sales and Service Network

-

Most trusted by many recognised

Brands in India -

Honored with Recognitions and

Certifications

Trusted by Brands

© Ensavior Technologies Pvt. Ltd. 2024 All rights reserved · Privacy- and Cookies Policy · Terms of Use